Products Description

Brief Introduction

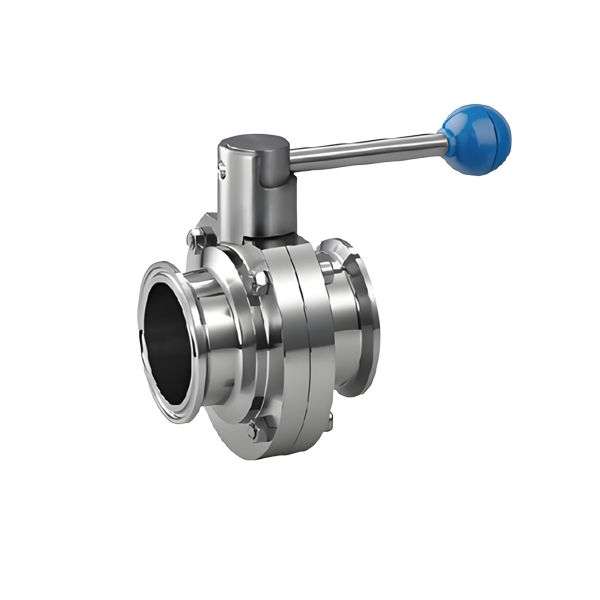

Sanitary Quick-Connect Butterfly Valves represent an advanced evolution in hygienic process flow control, integrating the reliable quarter-turn operation of traditional butterfly valves with innovative quick-disconnect mechanisms. These specialized valves feature standardized sanitary clamp connections (such as Tri-Clamp, DIN, or ISO standards) that enable tool-free installation and removal, significantly reducing maintenance downtime in critical processing applications.

Manufactured from premium 316L or 304 stainless steel with electropolished finishes (Ra ≤ 0.38 μm), these valves incorporate FDA-compliant sealing materials including EPDM, FKM, and platinum-cured silicone. The quick-connect design maintains a smooth, crevice-free flow path while ensuring perfect alignment and leak-tight integrity, making them ideal for applications requiring frequent disassembly and stringent hygiene standards.

Features

1. Unmatched Operational Efficiency

Tool-free installation and removal reduces maintenance time by up to 70%

Quarter-turn operation enables instantaneous flow control

Self-aligning clamp connections ensure perfect positioning

2. Superior Hygienic Design

Zero dead space construction prevents bacterial harborage

Electropolished surfaces (Ra ≤ 0.38 μm) inhibit microbial adhesion

Fully drainable design supports complete product recovery

3. Enhanced Process Integrity

Bubble-tight sealing performance prevents leakage

CIP/SIP compatible for validated cleaning processes

100% surface contact ensures consistent seal integrity

4. Exceptional Durability

316L stainless steel construction resists corrosive sanitizers

Reinforced disc-stem connection withstands repeated cycling

Temperature resistant from -20°C to 150°C

5. Compliance and Safety

3-A, FDA, EHEDG, and cGMP compliance

Visual position indicators prevent operational errors

Material traceability and full documentation support

Application Scenarios

Pharmaceutical Manufacturing: API processing, buffer preparation, CIP systems

Biotechnology: Fermentation systems, cell culture media, purification processes

Food & Beverage: Product transfer lines, ingredient batching, filling systems

Dairy Industry: Milk processing, yogurt production, cheese manufacturing

Cosmetics: Cream manufacturing, lotion processing, ingredient handling