Products Description

Brief Introduction

Crushing and Screening Equipment: The Efficient All-in-One Solution for Powder Processing

Crushing and Screening Equipment is an integrated mechanical system that combines the two processes of crushing (grinding) and screening (classification) into one seamless operation or closely interlinked system. It is designed to break down lumpy or granular raw materials into smaller particles through mechanical force, immediately screening them to separate the finished product that meets the target particle size requirements. Oversized particles are automatically returned for further crushing, forming an efficient closed-circuit cycle processing system.

Its core value lies in integrating two originally independent processes into one, achieving a continuous crushing-classification-recrushing workflow, significantly improving production efficiency and product quality consistency.

Typical Workflow: Feeding and Crushing: Raw material enters the crushing chamber and is broken down by high-speed rotating hammers, blades, or grinding discs.

Pneumatic Conveying and Screening: The crushed material is transported via negative pressure airflow or mechanical means to the screening mechanism (e.g., vibrating screen, rotary sieve).

Particle Size Classification: Fine particles (acceptable product) pass through the screen mesh and are collected as the final product; coarse particles (unacceptable) are retained by the screen.

Recirculation and Recrushing: Coarse particles are automatically returned to the crushing chamber via a recirculation system (e.g., screw conveyor, airflow) for further grinding until they all pass through the screen.

Features

This integrated design offers significant multi-faceted advantages for powder production.

1. Exceptional Production Efficiency and Automation

Continuous Operation: Eliminates inter-batch downtime, enabling seamless material flow from input to finished product output, increasing production efficiency by 30%-50% compared to traditional separate equipment.

High Degree of Automation: The entire system can achieve fully automatic control, significantly reducing the need for manual feeding, transfer, and monitoring, thereby lowering labor intensity and human error.

Instant Screening Prevents Over-Grinding: Material is separated immediately upon reaching the target particle size, effectively preventing acceptable fine powder from being repeatedly subjected to mechanical force in the crushing chamber, saving energy and preventing material overheating or property changes.

2. Superior Product Quality and Consistency

Strict Particle Size Control: By precisely selecting screen meshes of different sizes, the particle size distribution of the final powder can be strictly controlled, ensuring every batch meets stringent specifications.

Uniform and Stable Quality: The closed-loop system ensures all particles meet uniform standards, offering product consistency that is difficult to achieve with separate, multi-step processing.

Minimized Contamination Risk: The system is typically fully enclosed, effectively preventing external impurities from entering while also controlling dust, ensuring product purity and a clean production environment.

3. Significant Operational Economy

Space Saving: One combined unit replaces multiple standalone machines like crushers, elevators, and screens, drastically reducing the equipment footprint.

Reduced Energy Consumption: Avoids the energy costs associated with cooling, storing, and reprocessing unacceptable coarse powder, resulting in lower overall energy consumption.

Lower Labor Costs: Automated operation means fewer operators are required, leading to significant long-term savings in human resources.

4. Flexible Adaptability and Ease of Maintenance

Modular Design: Can be flexibly configured with different types of crushing units (e.g., universal crusher, turbo mill) and screening mechanisms based on material characteristics (e.g., hardness, viscosity, moisture content) and capacity requirements.

Easy Cleaning and Maintenance: Equipment often features quick-open designs for fast cleaning and replacement of wear parts (e.g., screens, hammers), particularly suitable for industries like pharmaceuticals and food with high hygiene and frequent product changeover requirements.

Application

The integrated crushing and screening system is the ideal choice for industries requiring precise control over powder particle size:

Pharmaceutical Industry: Crushing and screening of traditional Chinese medicine powders and Western drug raw materials, ensuring powder fineness meets formulation requirements (often compliant with GMP standards).

Food Industry: Grinding and fine screening of spices, sugar, grains, and additives.

Chemical Industry: Processing of pigments, dyes, resins, fertilizers, and other materials.

Metallurgy and Mining: Deep processing and particle size classification of mineral powders.

Parameters

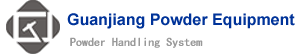

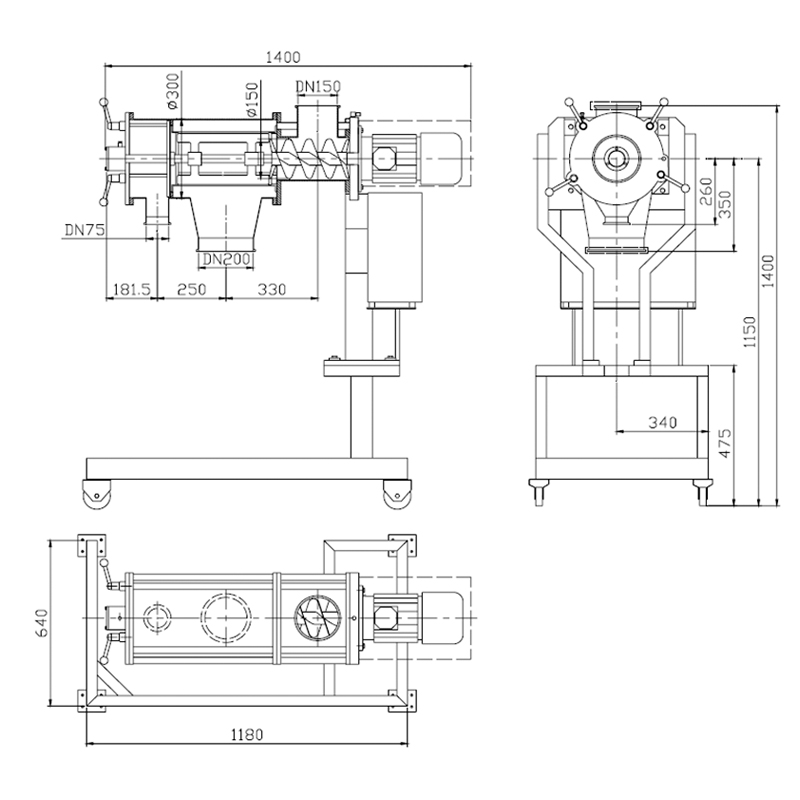

Model | Capacity | Voltage | Motor speed | Power | Mesh number | Particle Diameter | Weight |

SF-200 | 200~800L/h | 3×380V | 250~750r/min | 1.5KW | ~80 | < 8mm | 220kg |

50Hz | 250~750r/min | 2.2KW | |||||

SF-250 | 400~1000L/h | 3×380V | 250~750r/min | 2.2KW | ~80 | < 8mm | 250kg |

50Hz | 250~750r/min | 4.0KW |